Non-Destructive Testing, Inspection, and Evaluation Services

North Country NDT, LLC provides Non-Destructive testing of pressure vessels, storage tanks, process piping, and paper machine dryers.

Our team of inspectors provide accurate and reliable inspections to retrieve the data required of your engineering and / or insurance specifications. We obtain the data through a combination of Ultrasonice, Magnetic Particle, Dye Penetrant, and Visual (Remote / UAV / Underwater) Inspections. Our team has decades of collective experience to ensure you receive accurate, reliable data.

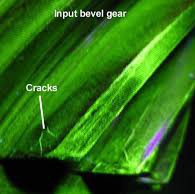

In 4Q20, our sister company, North Country Mechanical LLC, was formed and began offering mechanical services in response to increasing customer demands. These services are centered around, but not limited to, the dryer section of the paper machine. North Country Mechanical offers maintenance / rebuild services of rotary joints, syphons, turbulator bars, steam traps, gears, bearings & housings, and the overall steam system and dryer section.

Our number one goal is to provide our customers with accurate and dependable data, on-site and off. We offer on-site non-destructive inspection and evaluation services. Off-site, we offer such things as inspection and pressure vessel management programs.

All testing is carried out under the Codes and Regulations of ASNT, ASME or other governing bodies for each specfic test's requirements. We can also provide industry specific procedures and consultations based upon your specific requirments.

North Country NDT can provide you with the inspection services necessary to meet your engineering and insurance requirements.

Testing Services Provided by North Country NDT:

Remote Visual Inspection is a process using remotely controlled equipment which allows our inspectors to view objects and materials from a safe or distant location when the assets are inaccessible or in dangerous environments. Aerial drones, underwater drones, and borescopes are some of the equipment used for these examinations.

Direct Line From Our Technicians to YOU!

North Country NDT is a customer-oriented company which works directly with our customers – there are no middle men. The technicians which perform the inspections and provide you the detailed data reports are the same people whom interact with you, our customer. Our team consists of technicians each with 10+ years experience performing non-destructive inspections..

If you have any questions or need additional information about the inspections we perform, to help ensure and certify your production assets, please contact us at:

North Counrty NDT, LLC

Ticonderoga, NY 12883

Phone: +1 (518) 216-4017

Email: info@northcountryndt.com